Preface

In the building industry use of steel has a well-defined function, i.e. it is intended to provide load-bearing capacity and safe and trouble-free use. In architectural structures, also visual effect of these structures is crucial. It is possible because steel is produced in an almost unlimited range of shapes, tapering forms, curves, colors, and finishes. Such structures catch the eye, they can delight and sometimes they are signposts. Finally, sometimes they become even symbols.

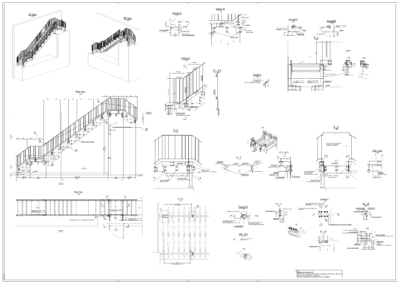

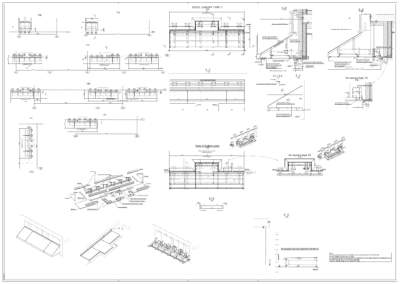

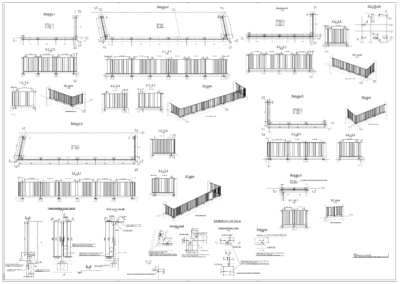

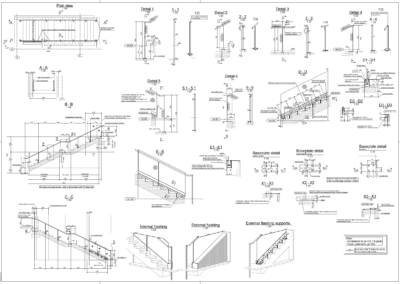

Some of them are encountered on a daily basis in residential and public buildings, ensuring functionality and safety of their use. Among them we can include: stairs (single runs or staircases), balustrades, balconies, external facades, canopies, skylights, external elevators, fences and many, many others.

Materials

In addition to carbon steel, stainless steel, corten (also known as rusting steel), copper, or alloys of various metals such as: bronze and brass are often used. Due to the different properties of the above materials, it is necessary to spend some time learning about them so as not to generate problems. Some practical examples below:

Welding of low carbon steel and pure copper

Due to the significant difference in the melting points of the two metals, for example, pure copper (or nickel) in form of welding wire is used as a filler. Otherwise, heat cracks may occur during welding.

Corrosion of galvanized components

Stainless steel is a noble material in most cathodic connections, while zinc and galvanized steel are ranked lower in the voltage series of metals – when combined with stainless steel it is more anodic in nature. If the stainless steel is combined with the galvanized steel and the electrical circuit is closed by an electrolyte (such as rainwater), corrosion of the more anodic material, i.e. galvanized steel, may take place.

Stainless steel processing

When it is processed with saws, brushes, etc. from ordinary (black) steel, the surface of the stainless steel becomes contaminated. Carbon steel particles become deeply embedded in the surface of the stainless steel, where they corrode after a short time. This manifests itself as rusty patches on the surface of the stainless steel.

For a unique, modern look, steel in the architecture is often combined with other materials like wood or glass. When it comes about the glass, it is mainly laminated glass that is used. This is reinforced glass (VSG). It is formed by joining together two or more sheets of glass with a special film. An advantage of this type of glass is safety – as a result of damage, the glass crumbles and breaks, but the pieces of glass are still glued to the film. Combining the right amount and type of glass together makes it possible to obtain glass with sound-absorbing, anti-burglary, or bulletproof properties.

Purchased components are also used, such as magnetic locks, fig. 1, manual locks, hinges of all types (e.g. self-closing), hydraulic actuators (e.g., in swing gates, hatches), or a wide assortment of handles (e.g., for attaching balustrade brackets, fig. 2 or glass panes, fig .3). It is necessary to familiarize yourself with their data and installation guidelines in order to properly prepare the steel structure for them. It happens that these types of elements are assembled already at the prefabrication stage (e.g. before the box steel elements are blinded or before painting).

Finishing

Hereunder there are only selected examples depending on the material:

Carbon steel

Zinc plating, powder coating with polyester and thermo plastic paints.

Stainless steel

grinding, brushing, coating the surface with other materials or polishing to: matte, satin fig. 4, mirror fig. 5. In case of the sheet metal – perforation and embossing fig. 6.

Corten

Fig. 7, which is steel with increased resistance; under influence of the moisture, it naturally covers itself with a characteristic coating resembling rust. A layer of copper oxide does not adversely affect the structure of the steel and it provides an additional layer of protection (in contrast to a “real” rust). However, it should be kept in mind that the steel must be well protected and there must be no gaps or cavities.

Cooper

Fig. 8 chemical patination or clear coatings to help preserving the natural color.

Glass

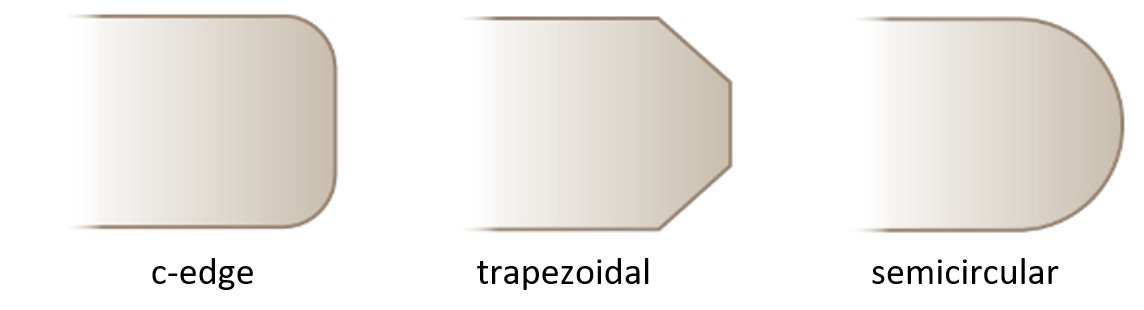

Although it not a steel, is still worth attention. It is available in both transparent and milky forms in a variety of colors. The edges are often ground and the most popular grinds are:

Bolts & screws

Unlike in case of industrial construction, due to architectural structures there is a much wider range of assortment available. In addition to hexagon-head screws, countersunk screws are often used. For fences or other structures such as bicycle cages, where loosening the screws will result in the loss of their function of protecting the interior, lock screws (with a ball head) are used from the outside. Part of the shank of such a bolt has a square cross-section, which wedges into a specially prepared hole of the fastened element, ensuring that the nut can be tightened from the inside.

Allen screws (with ball or flat heads) are also often used. Fine rivets (e.g., steel-aluminum), self-drilling fasteners (in a wide assortment), or adhesives are used for flashings.

Process

It all starts with discussions with the client, and this is usually handled by an architect. An architectural design is developed on the basis of which the engineer makes calculations and selects cross-sections of elements. Everything goes back to the client for approval. Next there is a detailer (the person who performs the detailed workshop design of the structure). He / she reads the documentation and draws up any technical questions. Sometimes this is a tedious and long-term process, including writing emails and attending meetings.

Steel structures in architectural buildings often require that the design consider the inventory of existing structures (such as reinforced concrete or masonry), so it is inevitable to rely on:

- Measurements from construction site (meter/dial gauge). Understanding the sketches received is sometimes more difficult than the structure itself, which is the task. In short, “what did the author have in mind?”.

- Surveys. If a building was erected according to the design then there are no more questions. Just slight corrections are implemented as to levels or location of elements in the plan. The situation is worse in case of changes implemented at the stage of the erection process and you have to make sure how a thing looks like finally, because it is not in the project.

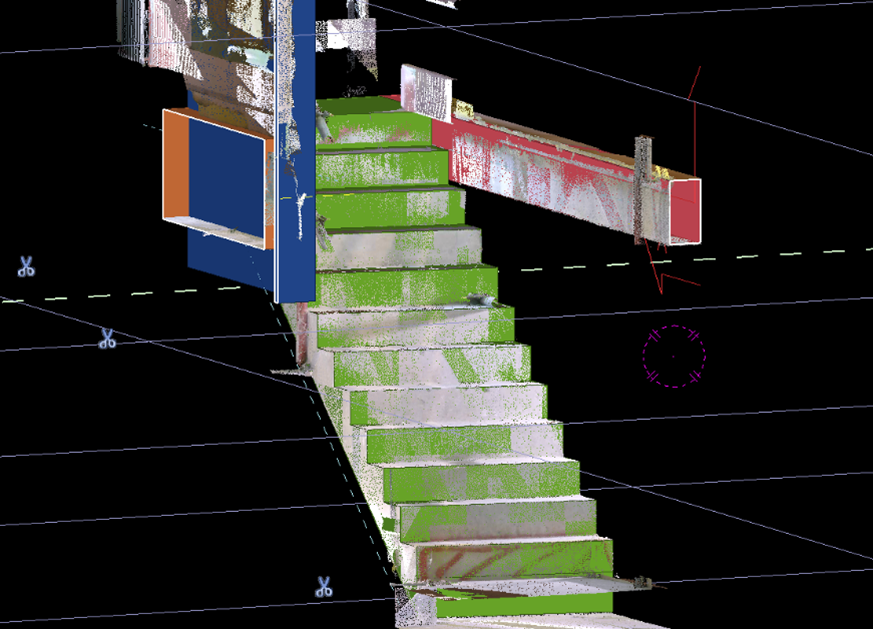

- Laser scanning and working with a cloud of points. The most precise method of inventory resulting in accuracy of several mm. The method is used for complex buildings. The view from Tekla Structures software shows a section of a reinforced concrete frame model, with a cloud of points previewed.

In our company we work on models of this type of construction in Tekla Structures software. Included in our models:

- reinforced concrete and masonry structures according to the inventory;

- important finishing layers that affect dimensions of a steel structure (e.g., the standard height of balustrades calculated from the finishing layer). Sometimes part of this type of structure requires additional finishing with thin metal sheets in order to hide certain elements or aesthetic transition between different types of materials, hence, finishing layers are necessary for us.

- steel structure;

- purchased elements – for example, brackets on the posts of balustrades for attaching glass fillings. They are useful in case of many issues: later counting of elements, preparation of glass elements for ordering and to show solutions on later drawings for approval.

- any other elements like: wooden steps of stairs, wooden handrails of balustrades, etc. This is necessary because, for example, glass is usually ordered on the basis of the workshop documentation made by the detailer of the mentioned elements. In addition, they must be shown and described on the drawings for approval.

Once the model is completed, the drawings are prepared for approval.

There are 3 basic statuses of such drawings:

- A – drawing reviewed, no comments, further work (such as the development of workshop documentation or production) can proceed.

- B – drawing reviewed with comments, work (as above) may continue with consideration given to the comments.

- C – drawing reviewed with comments, no authorization for further work, changes in accordance with comments are required; then issue drawing revisions for re-approval.

Approval of documentation depends on many aspects. Sometimes it is the first time, and sometimes it requires patience of the detailer and many revisions are required. Revisions occur for many reasons: the received documentation has deficiencies and you have to propose something by yourself, simple human error, changes by the architect or engineer, or customer indecision. Sometimes you even make a sample (make-up) on a scale of 1:1 of a fragment of the structure for approval (for example, a half-meter section of the balustrade) taking into account: all the materials used, fasteners, quality of welds and finishing.

Once the documentation is approved, the workshop and assembly documents can finally be drawn up and the contractor can proceed with prefabrication and assembly.

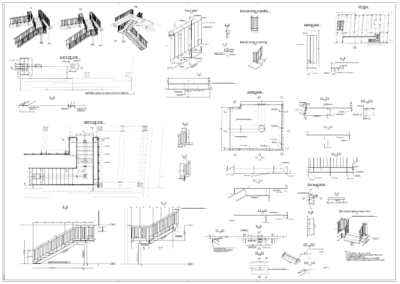

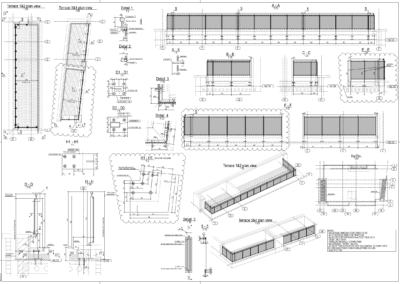

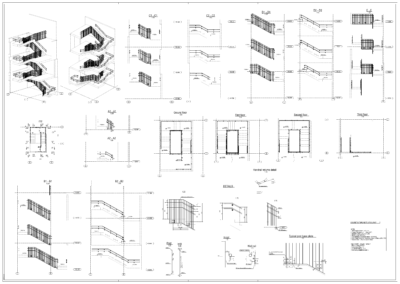

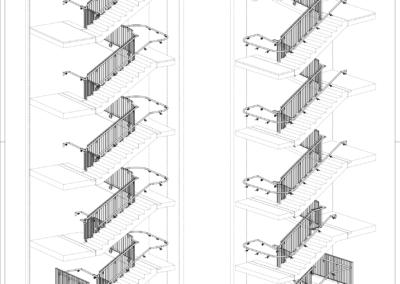

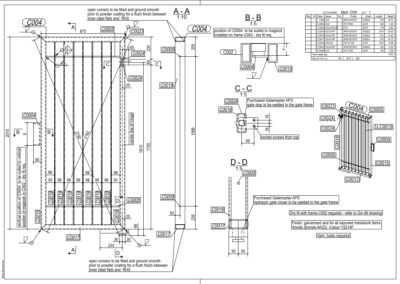

Below are some typical drawings from the design process.

Wojciech Świerad

Interested in this article? Have a comment or question? Enter a comment below.

Tags

#steel structures in architecture, #Tekla Structures, #stainless steel, #Corten, #steel balustrades, #glass balustrades, #steel surface finish, #steel fasteners, #drawings for approval, #steel stairs, #staircases, #balconies, #exterior facades, #roofs, #skylights, #fences, #cloud of points, #steelstructures, #workshop, #Bocad, #AVEVA, #Schuller & Company, #steel, #design, #steel structure design, #METIB, #Wojciech Świerad, #Marek Tomkowicz,